XL Group

International leading manufacturer

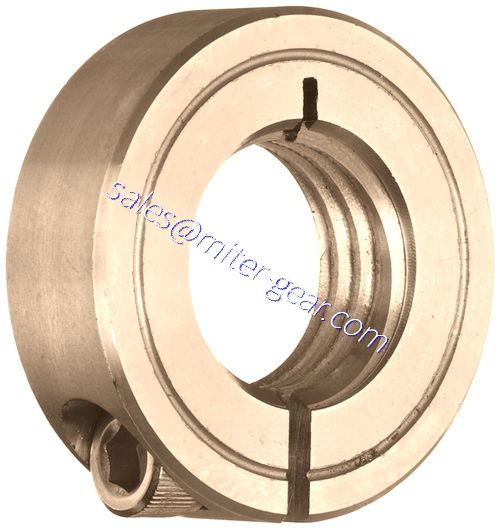

Shaft Collar

Easy to install

Wide range of USES

About XL Group

Company Profile

XL Group specializes in the production of various mechanical transmissions, such as: agricultural gearboxes, tractor gearboxes, automobile gearboxes, power transmission shafts and related gear components and other related products sprockets, collars, worm reducer, etc. In addition, we can produce customized transmissions, geared motors, electric motors and other products according to customers’ drawings. Our products have been exported to customers all over the world and have won a good reputation for our excellent product quality and after-sales service. Warmly welcome domestic and foreign customers to call to discuss business, exchange information and cooperate.

Professional production team

Products can be customized according to drawings or samples

Has the most complete testing equipment

24×7 service support providing quality services at anytime

Mainly exported to Europe, America and other parts of the world

Precision

Clamping Force

Bore Size

Materials

How does a Shaft Collar / Set Collar work?

Using an adjustable screw the set collar can be tightened securely and released freely.The screws on Clamp-style shaft collars act to compress the collar and lock it into place using friction. They are easy to use and do not damage the shaft. The compression of the screws on the collar imposes a uniform distribution of force on the shaft.

What does a Shaft Collar /Set Collar look like?

What does a Shaft Collar / Set Collar do?

Where is a Shaft Collar / Set Collar used?

What are the different types of shaft collars?

What are some design considerations for shaft collars?

About Shaft Collar

Shaft collars are used in many industrial equipment and systems, including: as positioning and alignment bearings, gears, pulleys and other moving parts. In laboratory equipment such as clamps and frames, shaft collars serve as precise and easily adjustable stops and spacers. In trucks and off-road vehicles, shaft collars act as mechanical stops for cylinders, actuators, and other components. During power transmission operations, the shaft collar assists in the positioning of the motor and transmission components.

Customer Testimonials

Our Main Products

Single Split Shaft Collars

Double Split Shaft Collars

Set Screw Shaft Collars

Threaded Shaft Collars

Threaded shaft collars can be both single and double split and as such can be installed both axially and radially. The internal threads of the clamp allow for more precise positioning along a threaded shaft.

Double Wide Shaft Collars